The Assembly Builder was developed to bring precision and efficiency to building performance modeling within cove.tool’s platform. I led the project end-to-end, from ideation and design to data modeling and implementation, to enable users build detailed building components for energy and embodied carbon calculations as well as load modeling.

Problem

Before Assembly Builder, users could only enter a single average R-value or U-value for each building component (e.g., all walls or roofs). To achieve accurate results, they had to calculate detailed assembly values manually and outside the tool, which was time-consuming and prone to error.

This limited both the accuracy of energy and carbon assessments and the ease of use for designers who had limited technical expertise.

There was a clear need for an in-platform feature that could handle layer-by-layer assembly definition while ensuring energy code compliance and data consistency.

My Role

As the Project Manager, I oversaw the complete lifecycle of the product:

- Defined the concept and functionality of the Assembly Builder to align with both user and business goals.

- Created wireframes, prototypes, and user workflows to illustrate and test the design direction.

- Designed and managed the database of materials and assemblies, integrating energy code–compliant options and material performance data.

- Authored detailed documentation and handoff specifications for the software development team.

- Collaborated with developers to validate data structure, calculations, and integration with the main cove.tool interface.

- Coordinated feedback across product, engineering, and leadership teams to ensure smooth delivery.

Process

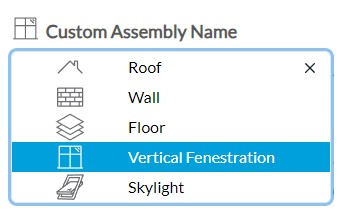

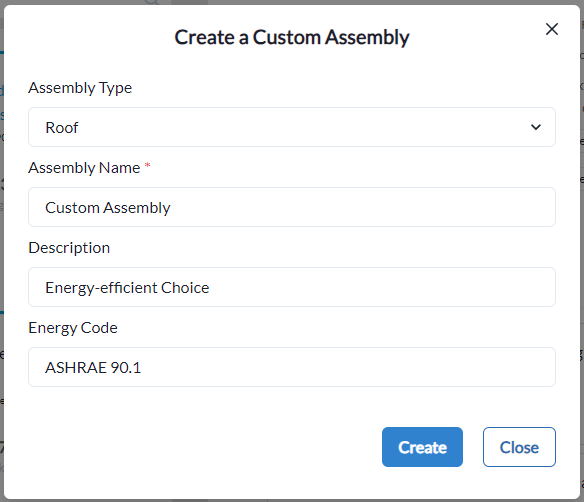

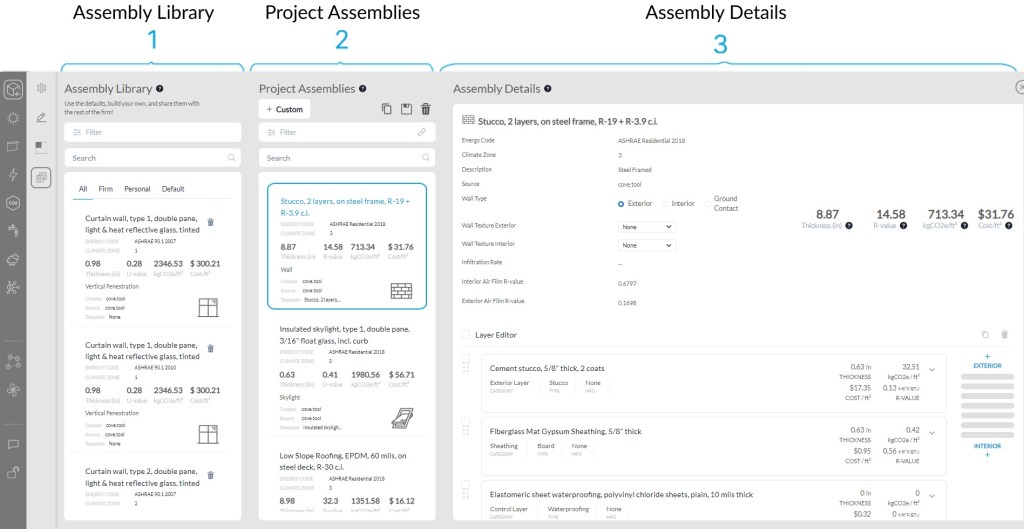

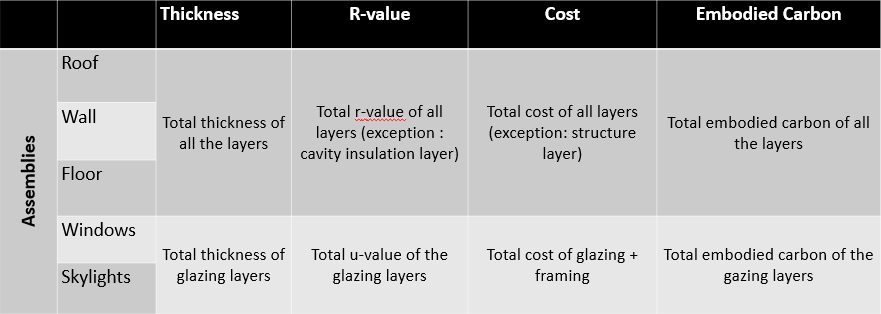

Starting from compiling feedback from users regarding pain points regarding manual, disconnected workflows, I conceptualized a tool that would let users construct building assemblies layer by layer using a visual and data-driven interface. The feature had 2 major parts:

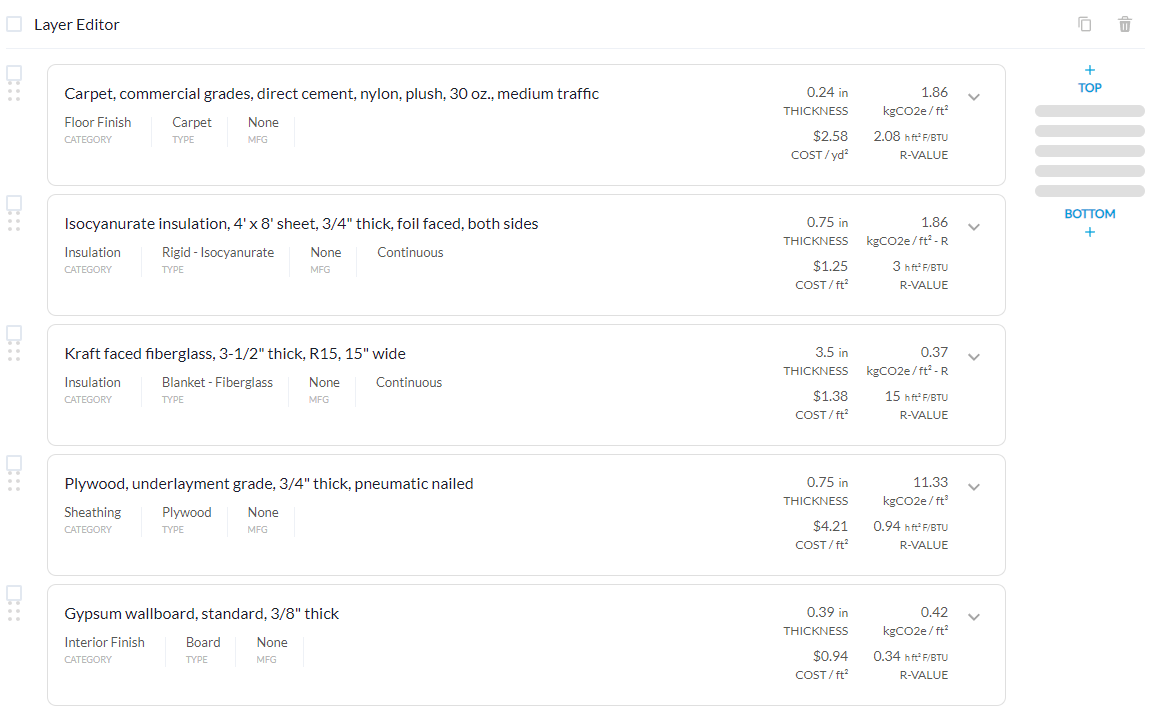

PRODUCT DATABASE

A database with hundreds and thousands of materials and predefined code compliant, generic and manufacturer specific assemblies. It was based on Uniformat and Masterformat classification, and consisted of thermal performance, embodied carbon and cost values for each material.

Link: https://help.covetool.com/en/articles/5952037-new-product-database

ASSEMBLY BUILDER INTERFACE

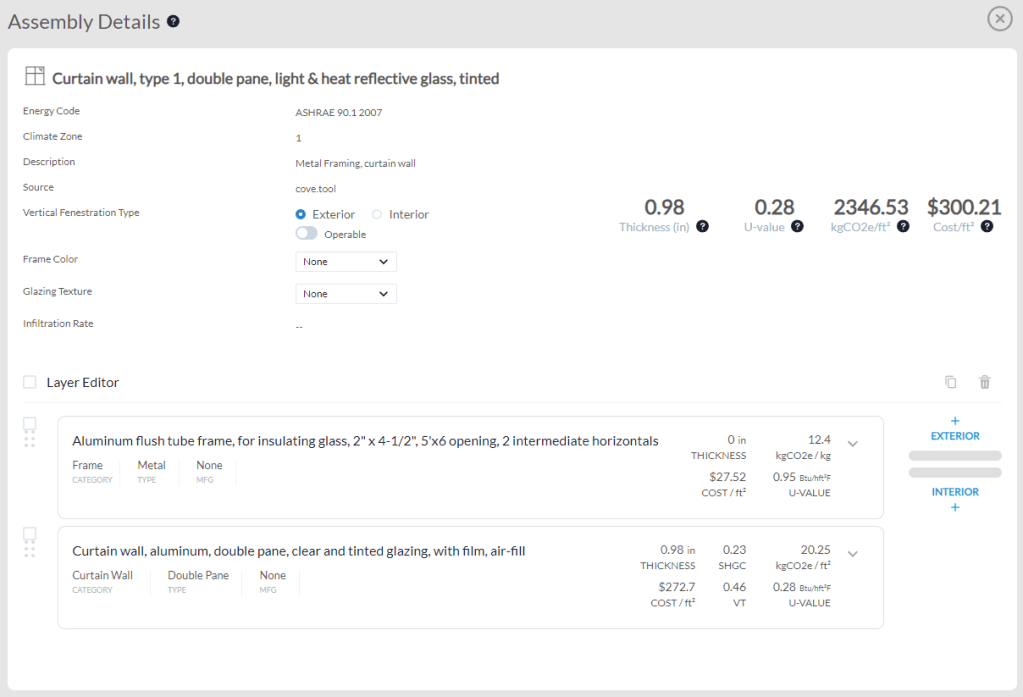

A frontend to enable users select each layer’s material from a predefined library and calculate/aggregate the total assembly values in real time.

Link: https://help.covetool.com/en/articles/6231951-assembly-builder

I designed multiple wireframes to explore how users could interact with materials, view cumulative results, and analyze energy and embodied carbon performance data. After feasibility testing with the development team, I refined the design into a final interactive prototype that balanced technical precision with usability.

The underlying material database became a cornerstone resource for other cove.tool features, storing properties like thermal performance, embodied carbon, and cost for hundreds of assemblies and materials in a one-of-a-kind database.

Tools Used

Figma (Wireframes, Interactive protoypes), Excel (Database), Word (Shared Design Documentation)

Outcome

The Assembly Builder transformed how users interact with performance data inside cove.tool. It replaced external manual workflows with a fast, reliable in-platform process, improving both accuracy and user confidence.

Key impacts:

- Streamlined setup for energy and carbon modeling workflows.

- Improved precision and standardization of performance inputs.

- Strengthened cove.tool’s position as an integrated platform for sustainable design analysis.

Reflection

Leading this project end-to-end reinforced my ability to connect data structure, user experience, and product strategy. The work demonstrated how thoughtful UX and well-organized information design can turn complex engineering tasks into clear, accessible, and scalable digital tools.